Relative News

Products

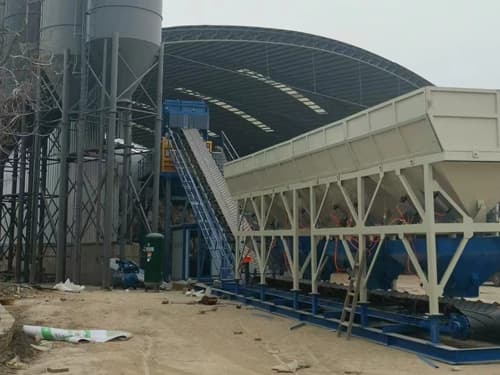

HZS60 concrete batching plant is a fully automatic concrete mixing equipment widely used in engineering construction. The following will provide a detailed introduction from its technical parameters, features, configuration, conveying and control system, etc.

Technical Parameters of HZS60 Concrete Batching Plant

- Theoretical Productivity: 60m³ of concrete can be produced per hour.

- Mixer: Minrui JS1000 twin-shaft forced concrete mixer is usually adopted.

- Overall Dimensions: 35m in length, 15m in width, 12m in height under working condition, and discharge height of 3.8-4.2m.

- Measurement Parameters: Cement measurement 1000Kg±1%, fly ash measurement 500Kg±1%.

- Aggregate Silo: Generally 4x12m³.

Main Features

Comprehensive performance advantages of HZS60 concrete batching plant

- Reasonable structural design: Adopting a modular structure, it is convenient for installation, disassembly and transportation, and has various arrangement forms, which can adapt to different site requirements.

- High mixing quality: The mixer has strong mixing capacity and high productivity, and can complete good mixing of dry-hard, semi-dry-hard, plastic and various proportioned concrete within the ideal time.

- Accurate and stable measurement: The measuring elements and control elements of all metering units are imported components, controlled by Siemens PLC, ensuring accurate measurement and stable performance.

- Good environmental performance: Powdered materials are processed in a closed state from feeding to mixing and discharging. Dust collectors are used in the mixing main building, and the main building and belt conveyor are packaged and enclosed, reducing dust and noise pollution to the environment.

- Convenient Maintenance: Each maintenance and service area is equipped with platforms or ladders, and the main engine cleaning is provided with a high-pressure pump cleaning device.

Unique advantages of Minrui Concrete Plant

Take Minrui Group HZS60 concrete mixing plant as an example:

- Anti-Leakage Design: A multi-shaft end seal protection device and an air pressure seal protection device are adopted to prevent slurry leakage from the mixer.

- Advanced lubrication system: A dedicated electric lubricating oil pump with four vertical pump cores supplies oil to four shaft heads respectively, no diverter valve required.

- High-quality electrical components: Using original Omron or Schneider contact switches, which are reliable and durable.

- Good quality of screw conveyor: The screw conveyor is made of high-quality steel pipe and has good rigidity.

- High safety: Multiple safety switches are installed in the control system.

Configuration Status

Basic Configuration

Batching System: PL1600, aggregate silo 4×12m³ ;

Aggregate Lifting System: 0.8m wide flat belt, 22KW motor, shaft-mounted reducer, weight tensioning device, upper and lower idlers;

Mixing Main Machine: Minrui JS1000 concrete mixer;

Mixing Main Building: Includes main building outriggers, finished product receiving hopper, etc.;

Water Metering System: Water Metering Box;

Cement Metering System: Measuring Bin;

Fly Ash Metering System: Measuring Bin;

Admixture Measuring System: Admixture Measuring Tank;

Pneumatic System: Air Compressor;

Electronic Control System: High-Voltage Cabinet;

Powder supply system (user-selected option): Screw φ219, quantity determined as needed;

Other configurations

The cement silo is a closed warehouse for storing materials such as cement and fly ash. The tank is equipped with a material level system, which can display the material position, and an arch breaking device can eliminate the clogging caused by material deposition.

Conveying and Control System

conveying system

- Aggregate Conveying: Feeding is done using a belt conveyor.

- Powder Conveying: The conveying methods for cement and fly ash are screw conveyors and pneumatic conveying. Among them, the screw conveyors generally adopt the LSY type, which are designed and manufactured in accordance with the CE standard.

Control System

The entire station is controlled by an industrial computer, which can be controlled automatically or manually, with simple operation and easy mastery. It has a dynamic panel display function, which can clearly understand the operation status of each component, and can store and print report data. Equipped with high-precision imported sensors, it has accurate weighing and rapid response.

Application Scenarios

Suitable for the production of large-volume concrete in large-scale projects such as roads, airports, ports, hydropower, etc., as well as prefabricated components, commercial concrete, etc.

Main sales areas

Africa, Europe, South America, Southeast Asia, North America, Northeast Asia, the Middle East, Latin America, etc.